Engineered-Fit Metal Shielding for Durable and Convenient Heat Reduction

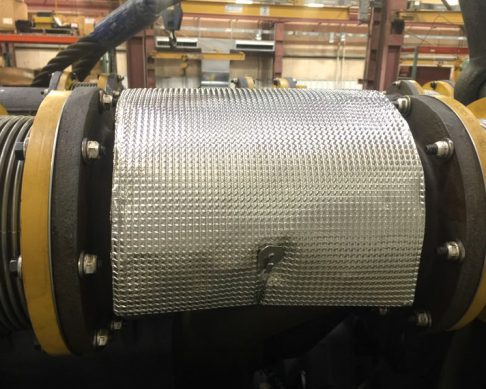

Gaining traction across all industries as a preferred heat reduction material is OCTI’s newest product, Metal Shielding. Our metal shields are rigid metal that encapsulates the insulation material, great for eliminating the possibility of water damage. With removable coverings that can withstand direct flame heat, these shields are much more durable than pliable thermal blankets.

Our unique manufacturing technique allows for the seams to be welded, eliminating the hazard of sharp edges that can injure personnel. With a wide range of uses, we have seen a significant adoption rate for bus systems, off-road construction equipment and refuse trucking in particular.

OCTI’s standard lead time is 10 to 15 business days. This turnaround time is the best in the industry, and we stand by our commitment to our customers to ship on time. Want to learn more? Contact us today.

Benefits of our Customized Design and Engineering

- Customer inclusion in every step of the way

- 3D modeling allows for changes during design phase to ensure correct fit and eliminate guesswork on look of product

- Highest level of durability with metal encapsulated insulation

- Dedicated designer assigned throughout life of project

- Access to engineers for field work and onsite support

- Knowledgeable installation team to work with your field personnel to install your heating solution

The Importance of Using Metal Shielding

Insulation blankets are used in so many industries and applications you would not be able to name them all. Our line of metal encapsulated coverings can be deployed in the most extreme conditions.

SAFETY

Refuse (Garbage) trucks carry some unpleasant material and operate in horrible conditions. Our metal shielding is durable enough to be installed on the exhaust of many of these trucks. Cleaning as much as possible is critical with refuse trucks. Our metal shielding allows for the trucks to conveniently be power washed, something not possible with soft blankets.

Better Heat Reduction & Lower Emissions

Lower emission requirements by state and local governments have resulted in the addition of Silencers and DPF’s to be used on engine exhaust systems. To meet emission requirements, the exhaust gasses must maintain elevated temperatures for the equipment to operate effectively. Covering these components and adjacent piping allows for exhaust temps to maintain levels above 1800 degrees allowing for equipment to burn carbon emissions rather than expel them.

High Temperature Insulation Applications

Metal Shielding is commonly used for:

- Power Generator Exhaust Piping

- Engine Exhaust Silencers

- Diesel Particulate Filters (DPF)

- Engine Turbo Units and Cylinder Covers

- Marine Exhaust and Engine Room Exposed Piping

- Refuse Truck Exhaust Systems

- Passenger Buses Exhaust Piping

Industries We Serve

We take pride in our top-notch teamwork to provide only the highest quality of products. Explore the services we provide for your industry and some project highlights showcasing our solutions.